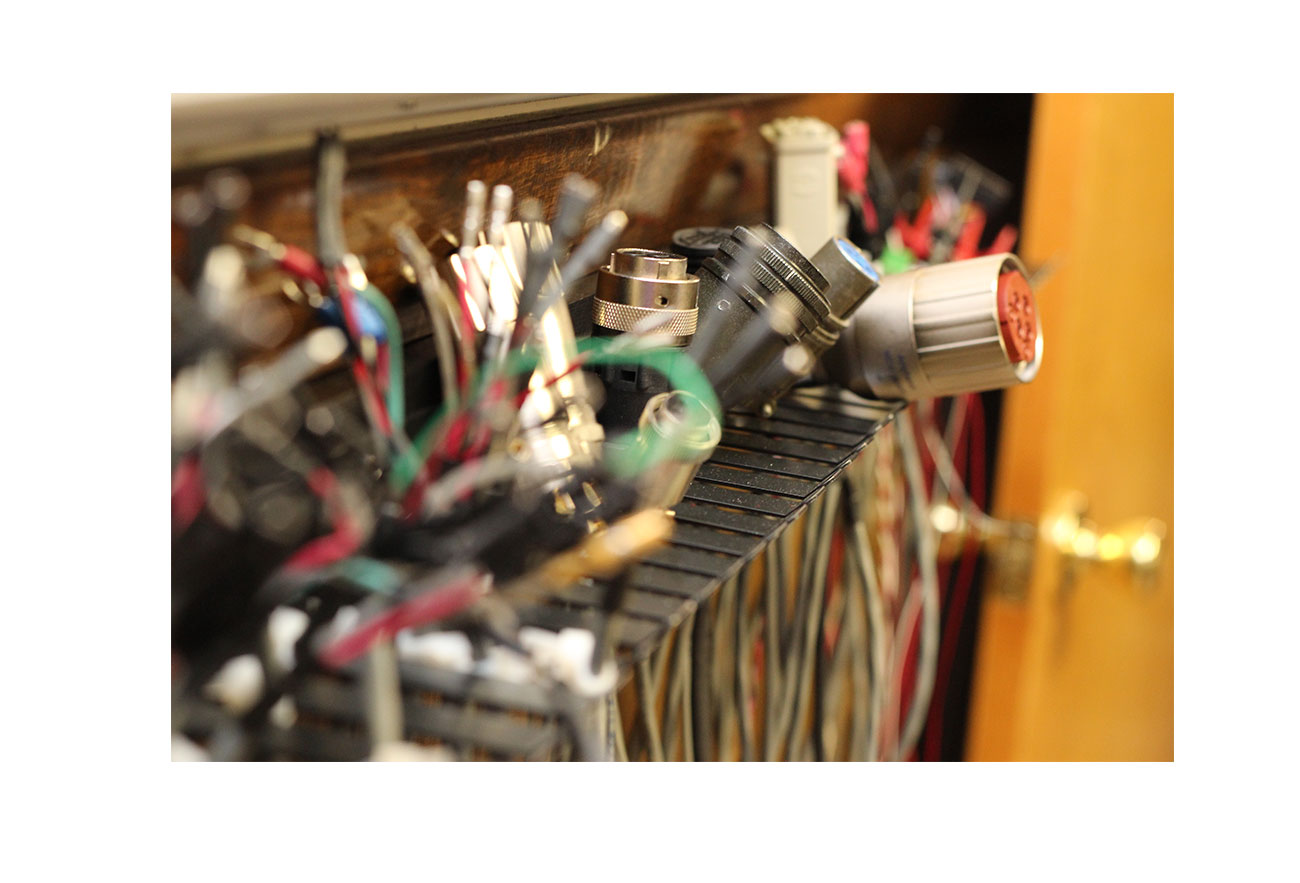

Vast Cable Assortment

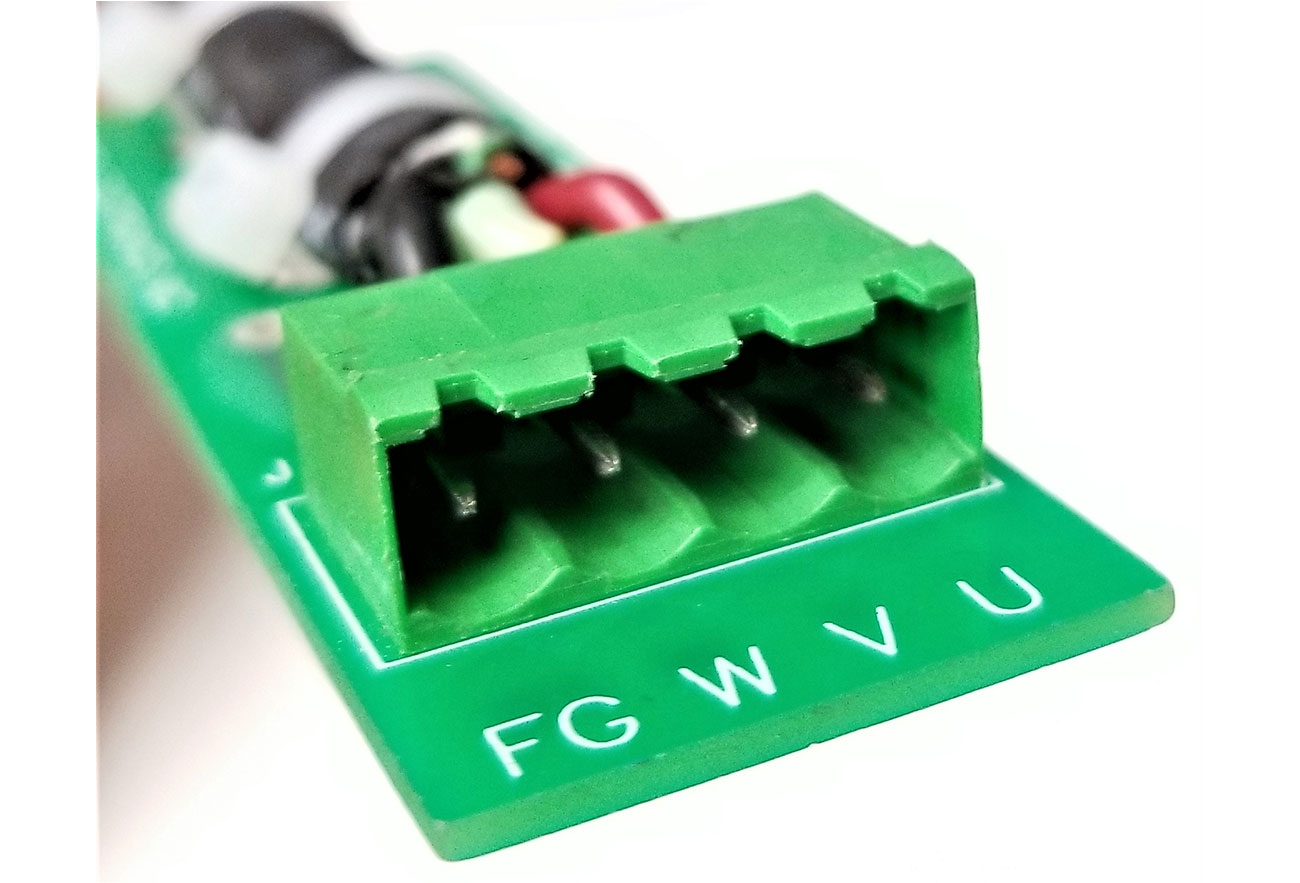

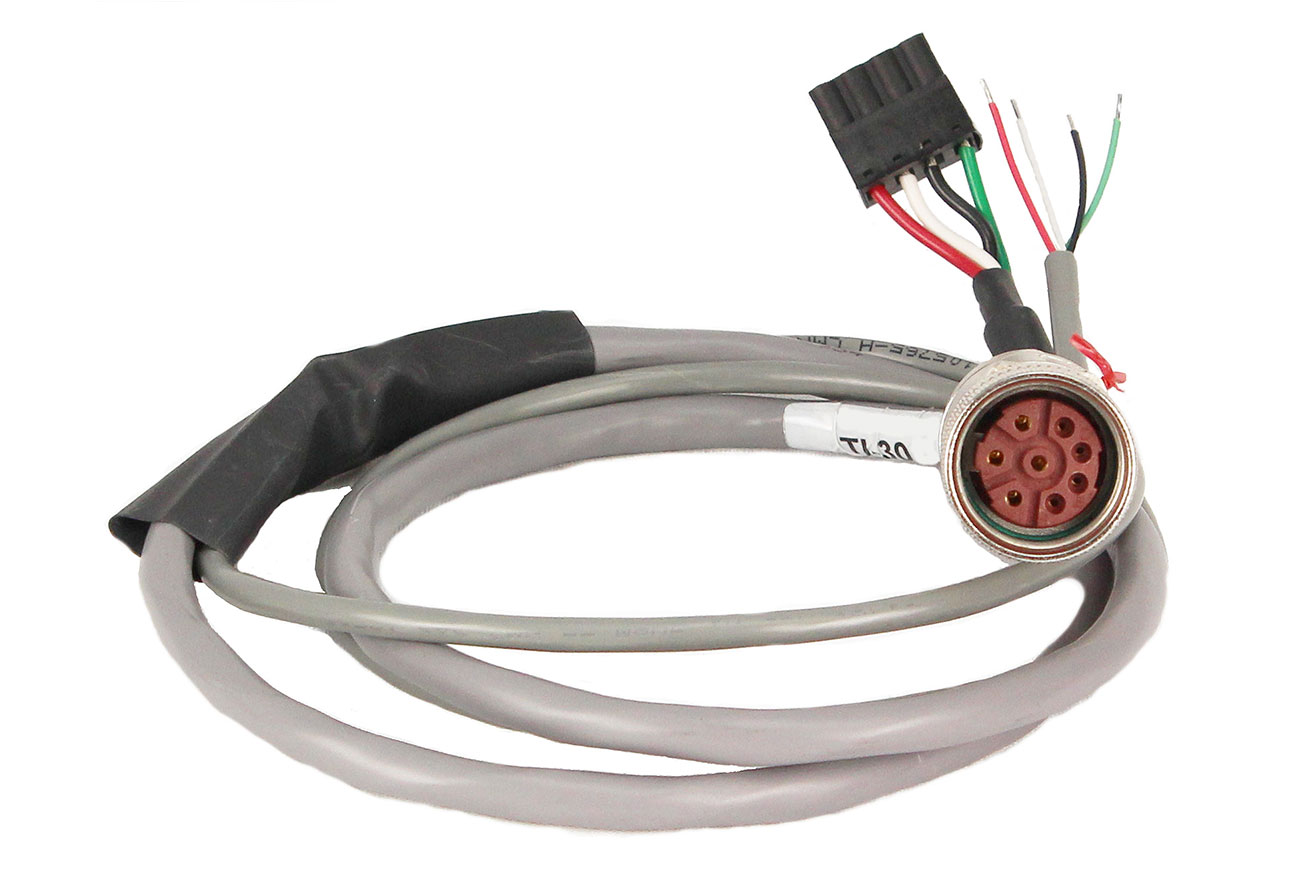

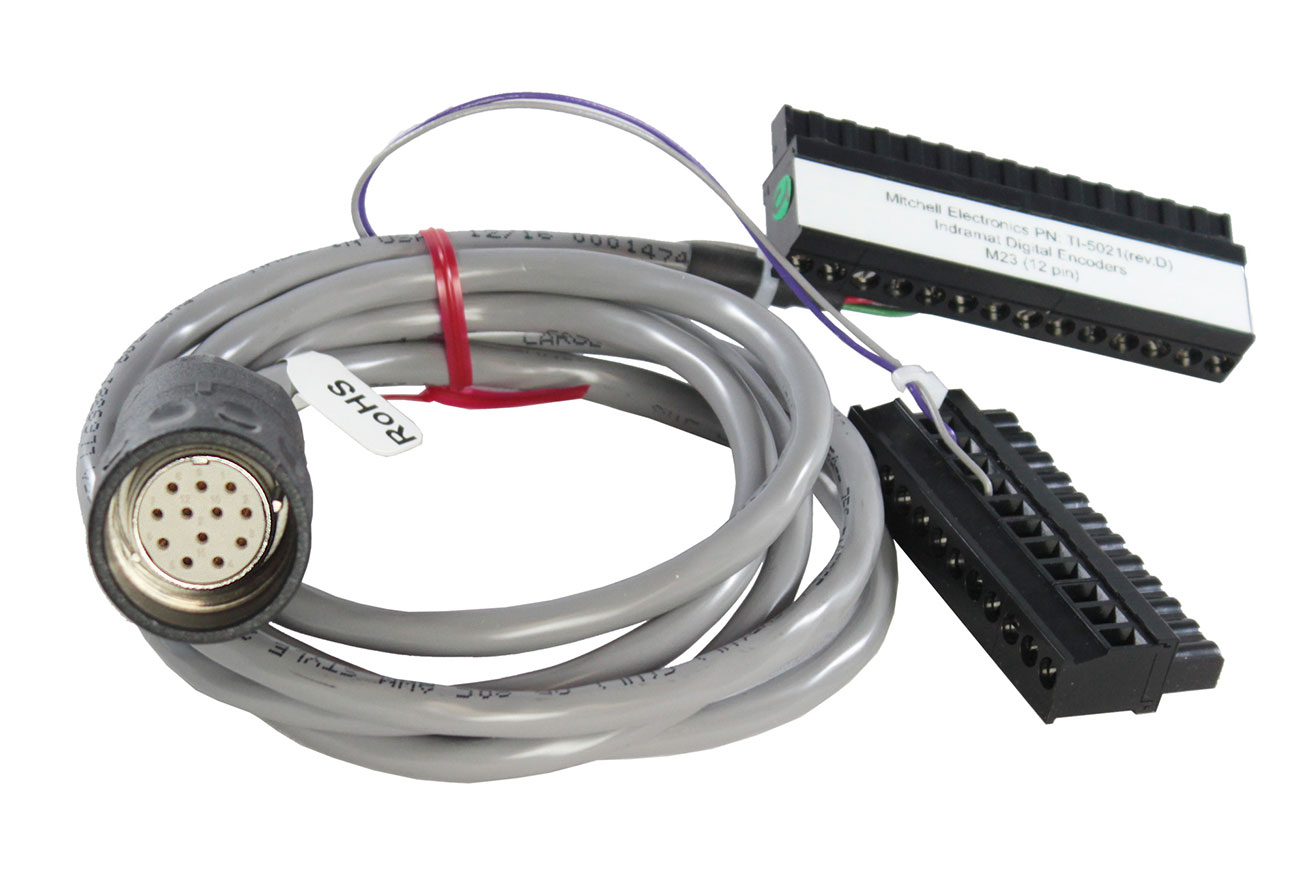

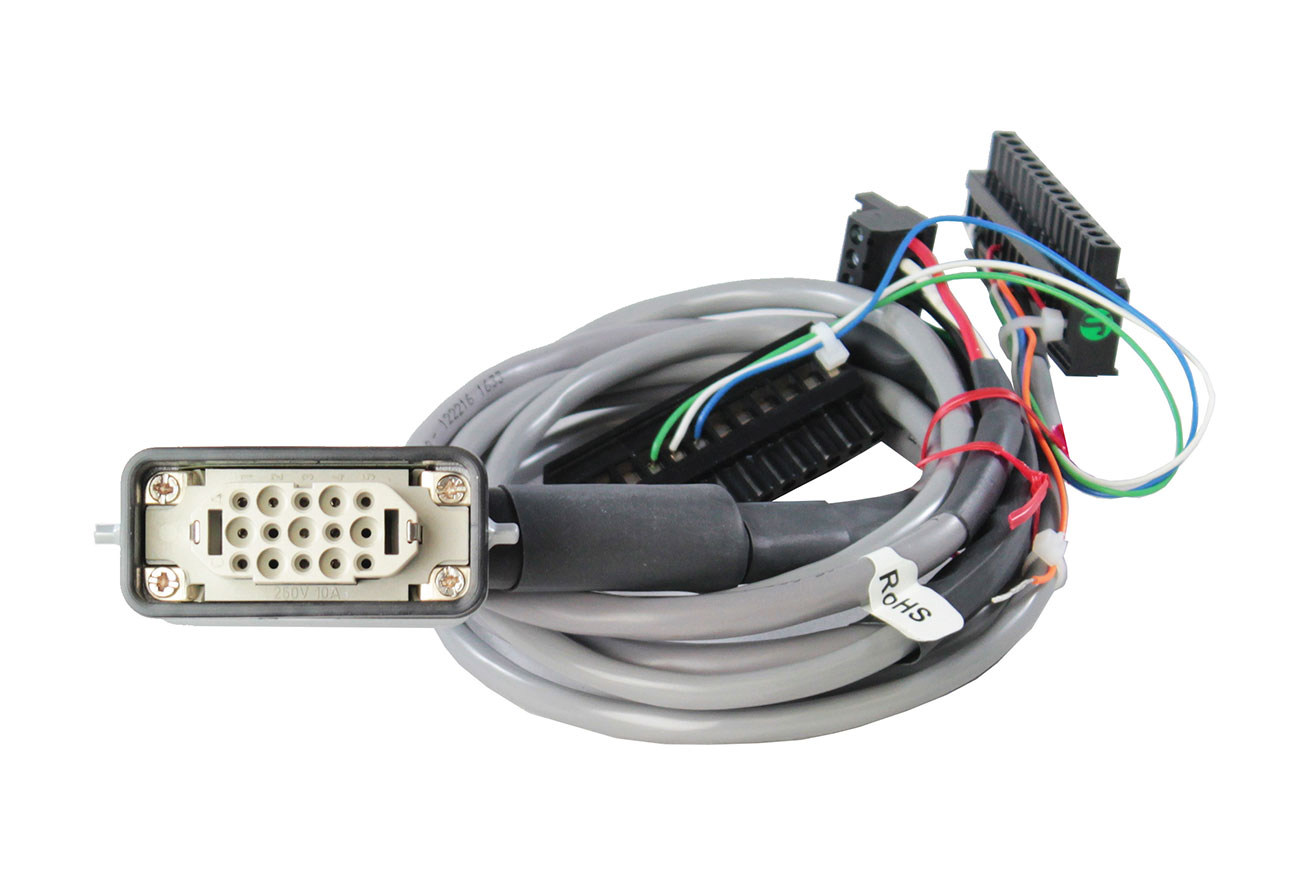

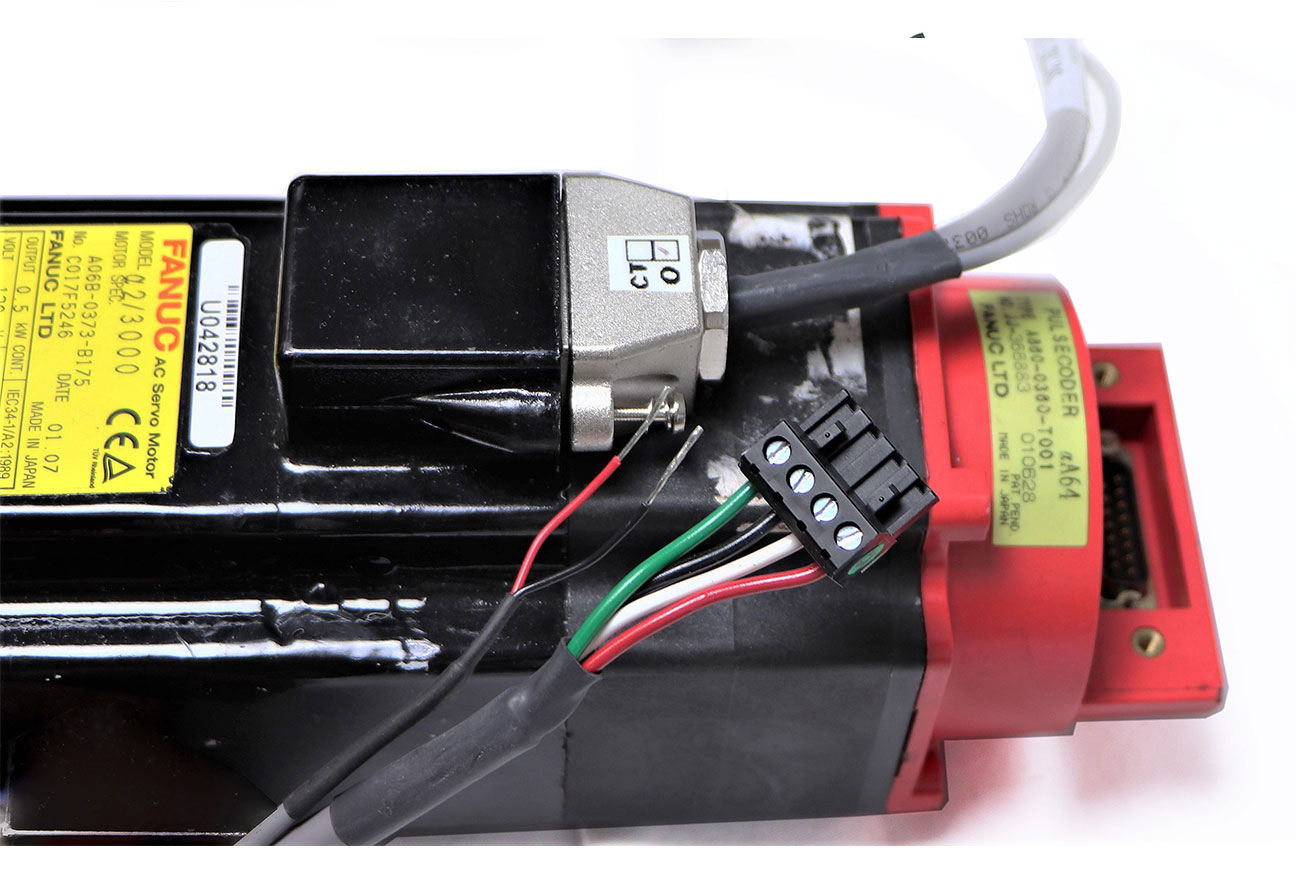

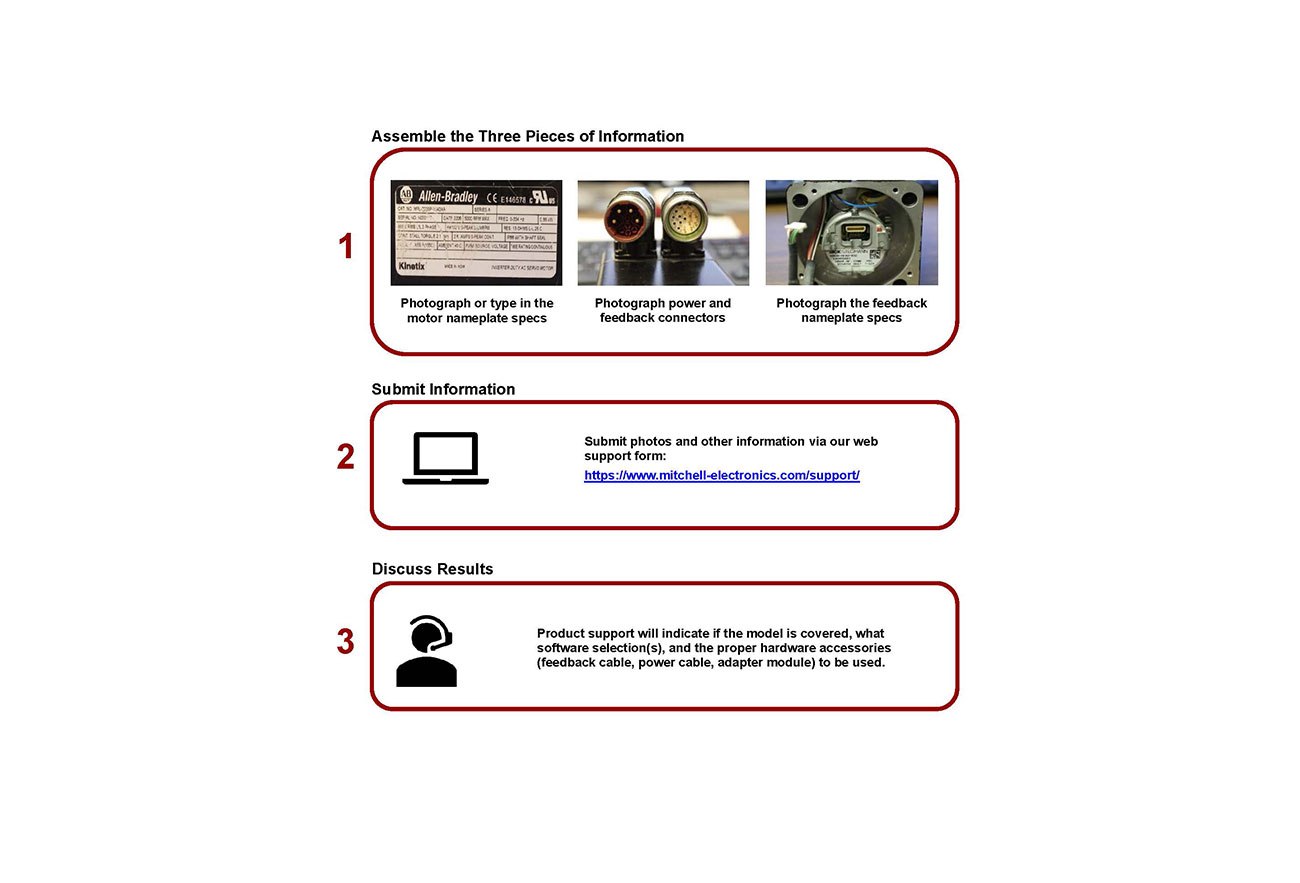

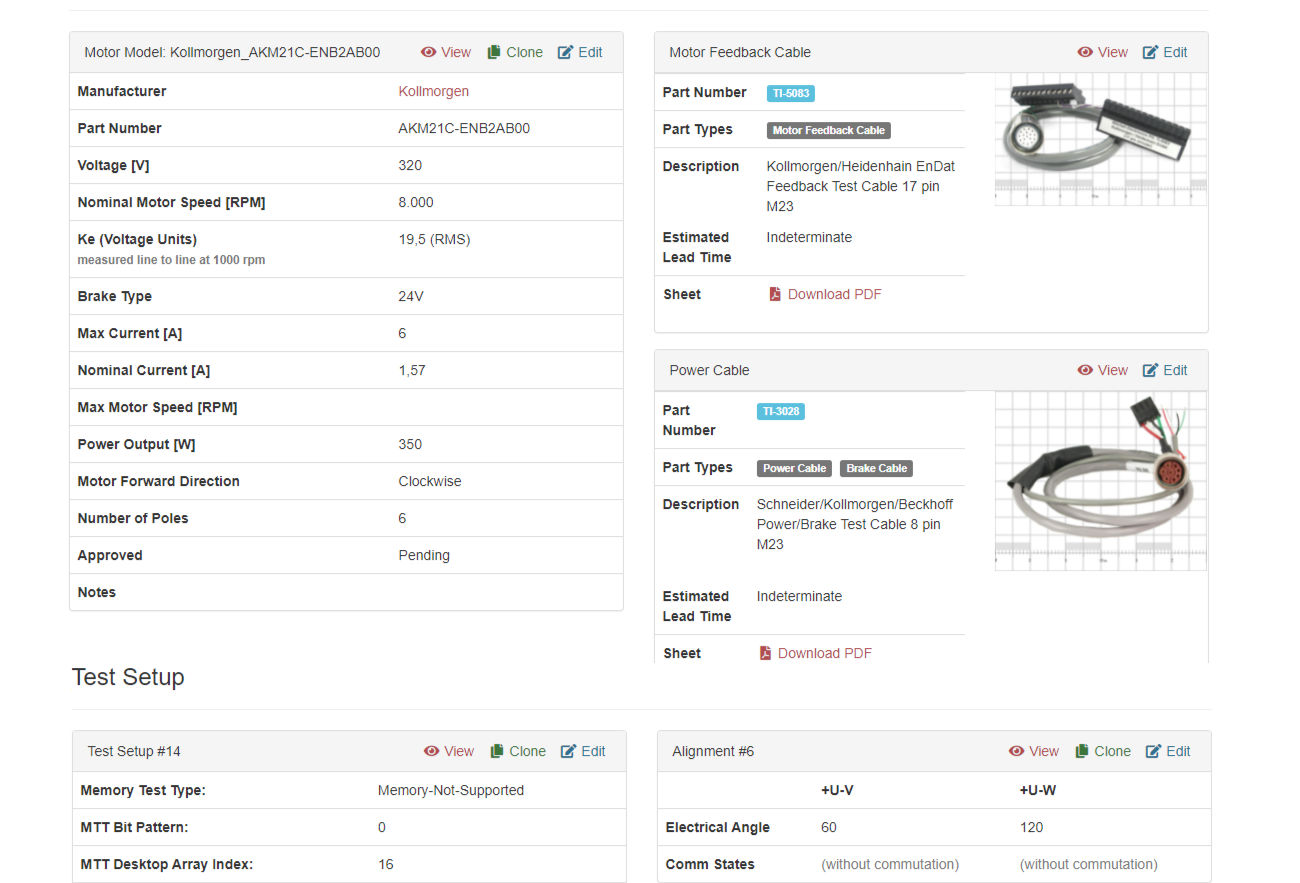

The process of diagnosing or repairing a servo motor involves locating the source of the problem, which can vary from a failed feedback device, a failed wire or connector, failed windings or magnets, or other wear issues such as failed servo motor bearings or shaft etc. The servo motor diagnostic process is already difficult enough, therefore it is important to reduce as many variables as possible. Ensuring that power is being correctly applied to the servo motor and that the feedback signals are being properly observed is of critical importance. This is best done with a cable specifically built for the particular servo motor part number under test. The Mitchell Electronics, Inc. catalog contains over 300 various power and feedback cables that are quality controlled before shipment to a customer by an in-house cable tester, allowing you to focus on the servo motor repair process instead of wondering about connector pinouts, or trying to ensure that all pins are properly connected during encoder diagnosis or servo motor run testing. Many servo motors have brakes, and these brake wires are included in our cables to aid in testing. This feature offers a simple connection to an external power supply which applies voltage to an electromagnetic coil in the servo motor to release the brake. The industry contains hundreds of different servo motor manufacturers and models using various types of connectors and connector pinouts. If a cable for your motor is not already in our catalog, contact us for a quote. In urgent situations, try one of our flying lead cables, with push-on pins, to ensure that connections remain intact especially while the motor rotates during a run test.